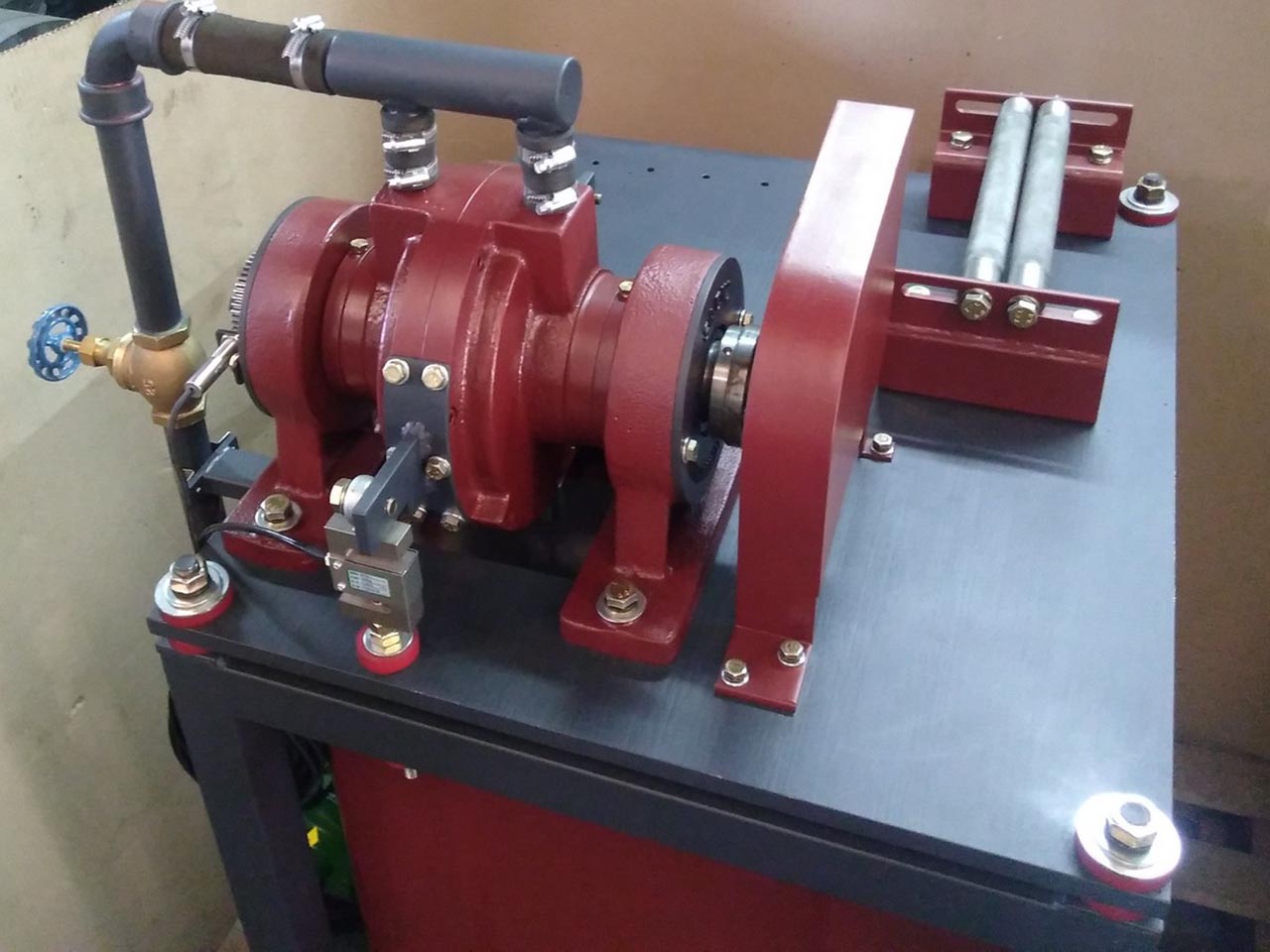

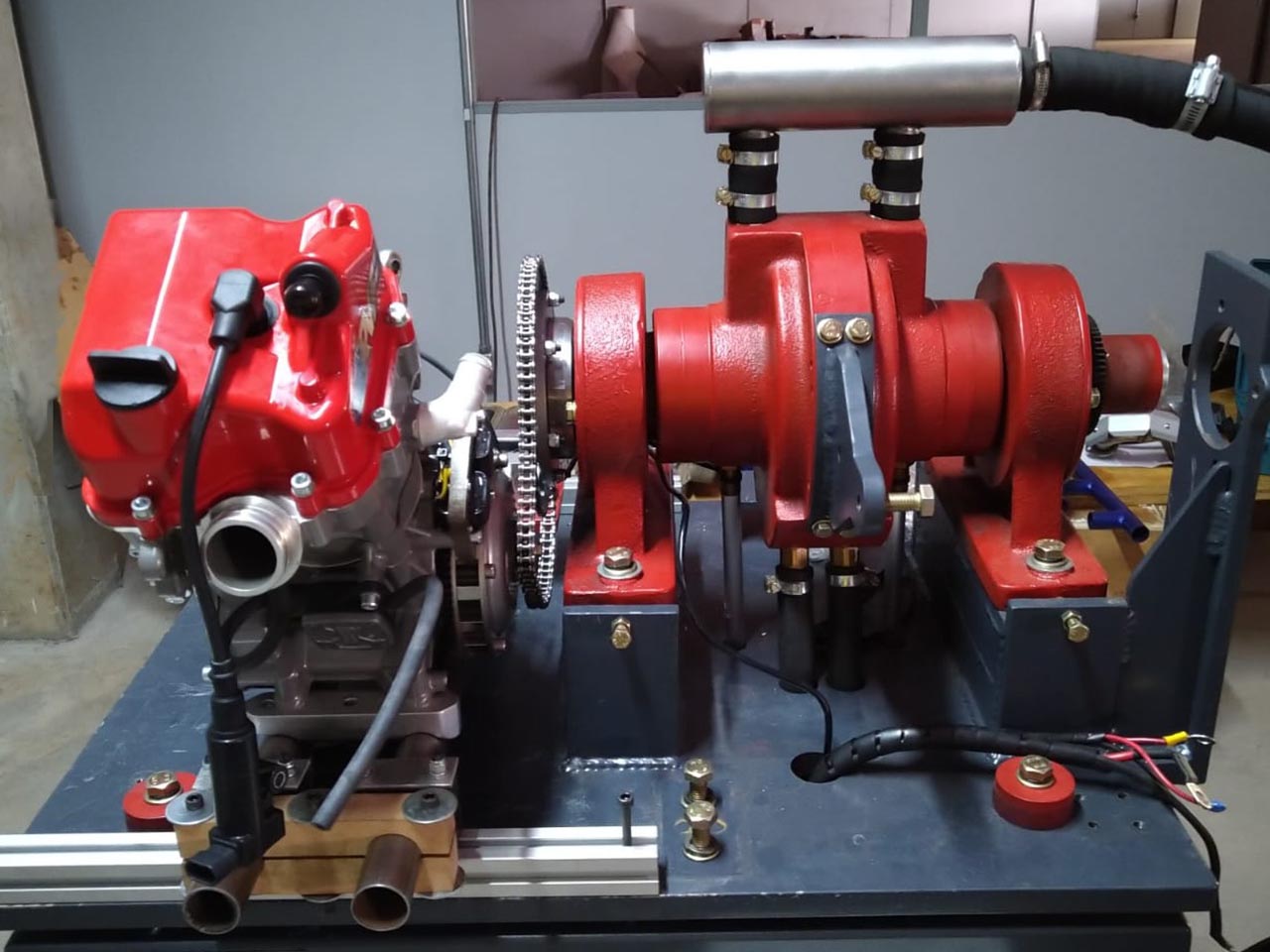

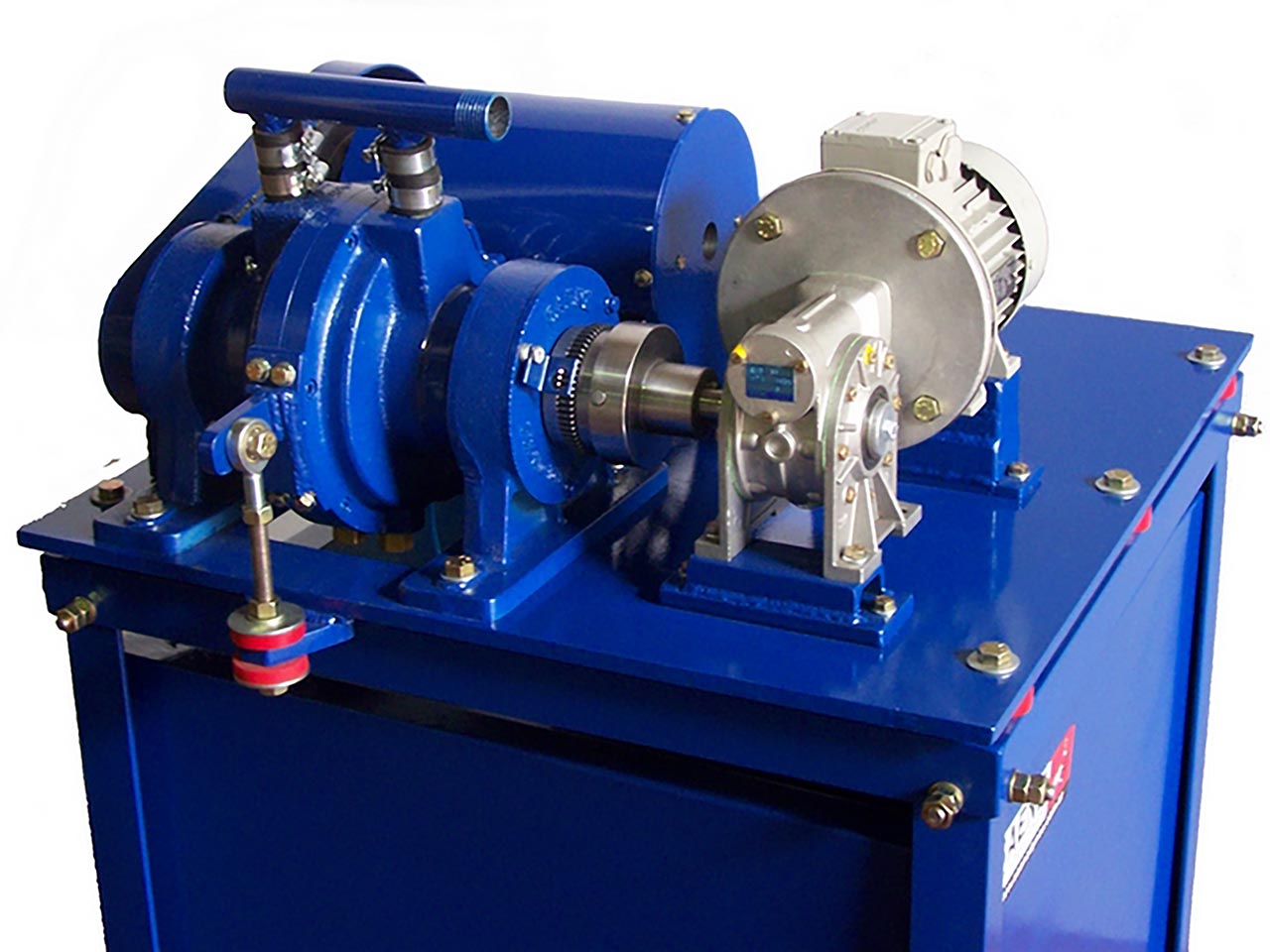

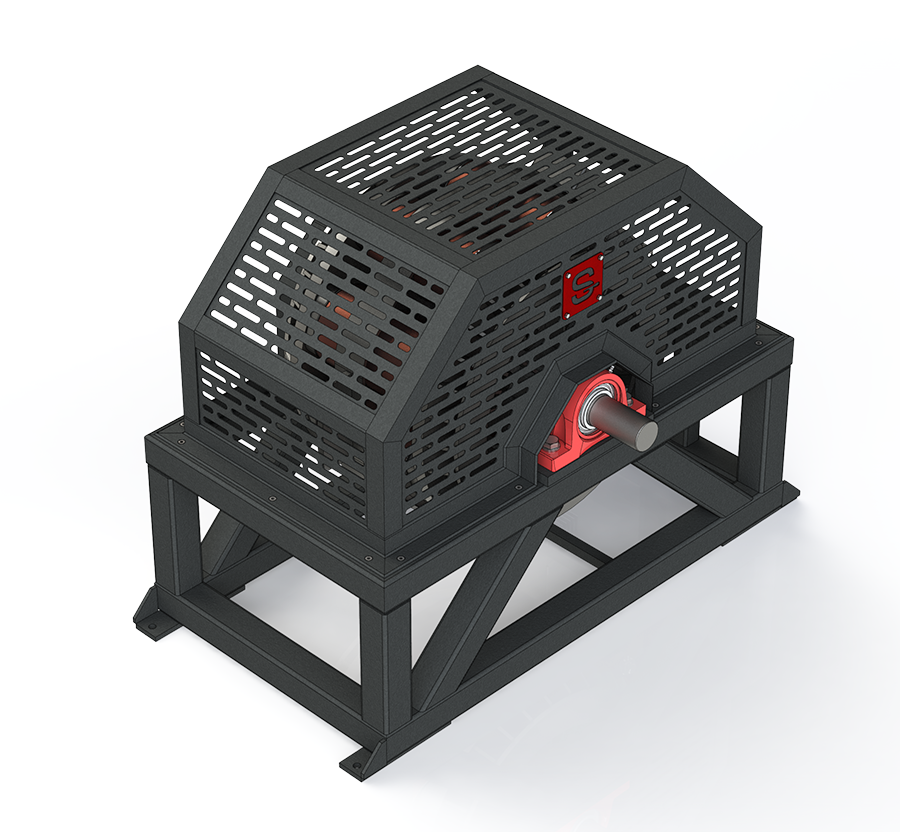

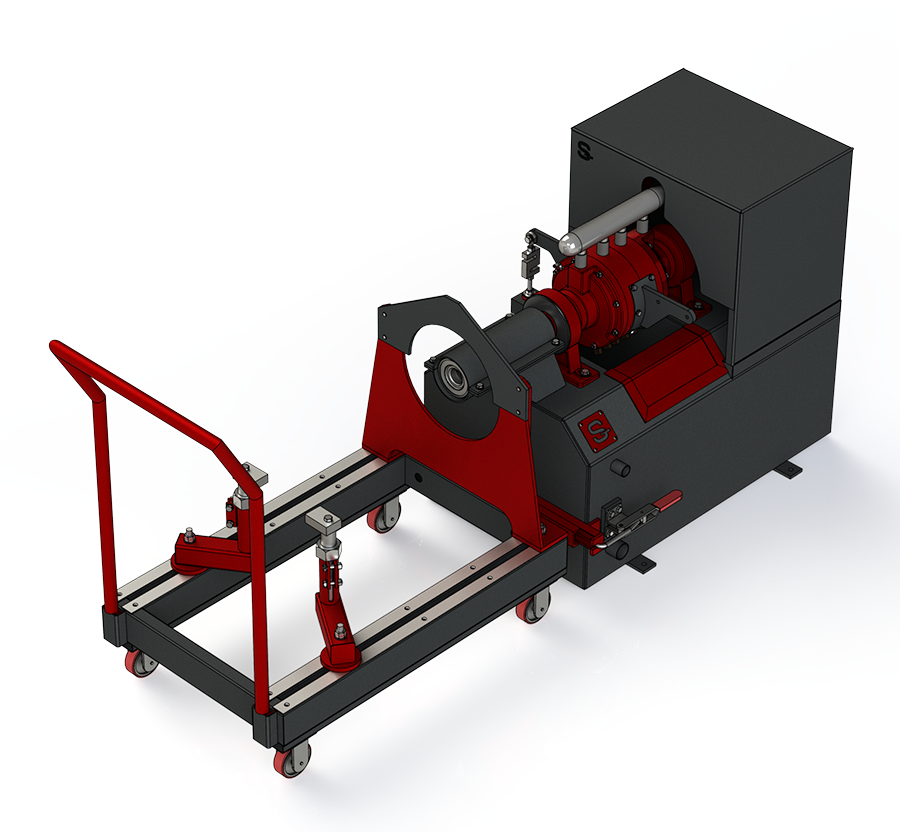

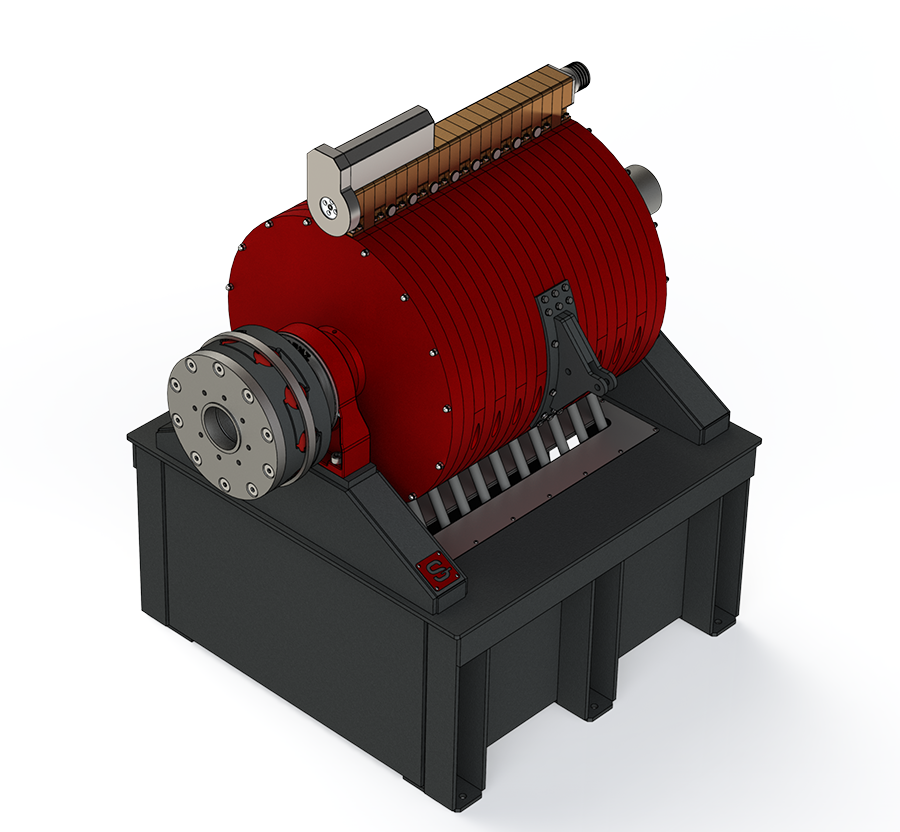

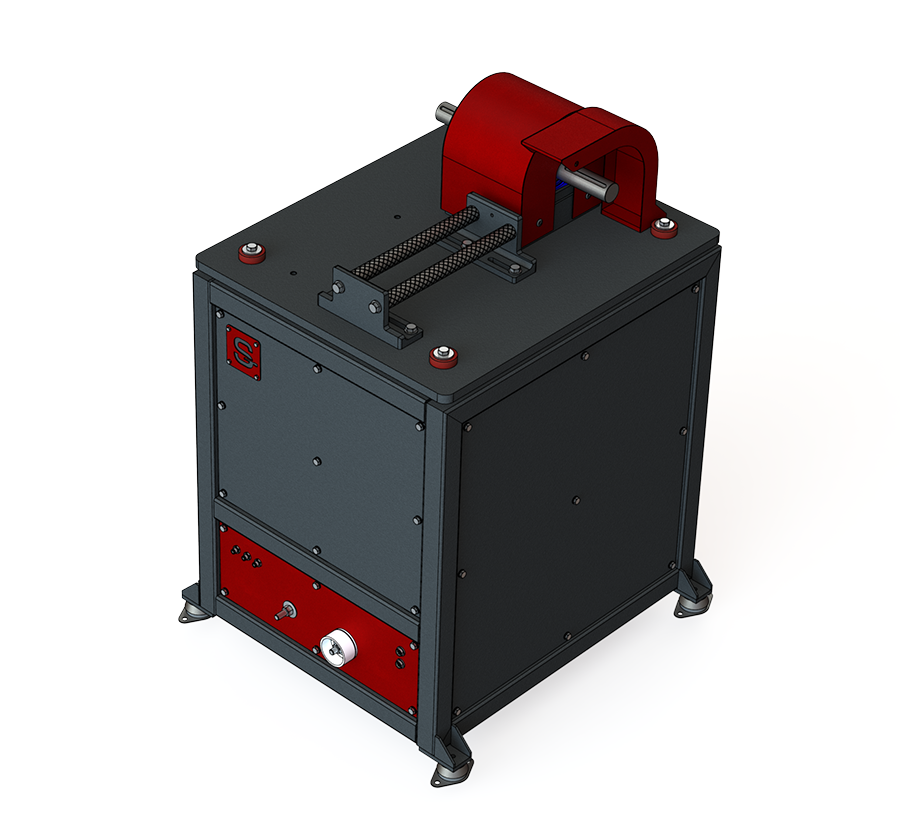

DK - Banco con freno hidráulico

Los Bancos de Prueba de Motores Saenz están diseñados para el ensayo profesional de motores. Desde 1974 fabricamos frenos hidráulicos de gran control, robustos, seguros y de bajo mantenimiento. Equipados con un sistema de adquisición de datos con control automático de RPM y Torque de motor que permite realizar ensayos con máxima precisión, sensibilidad y repetitividad.